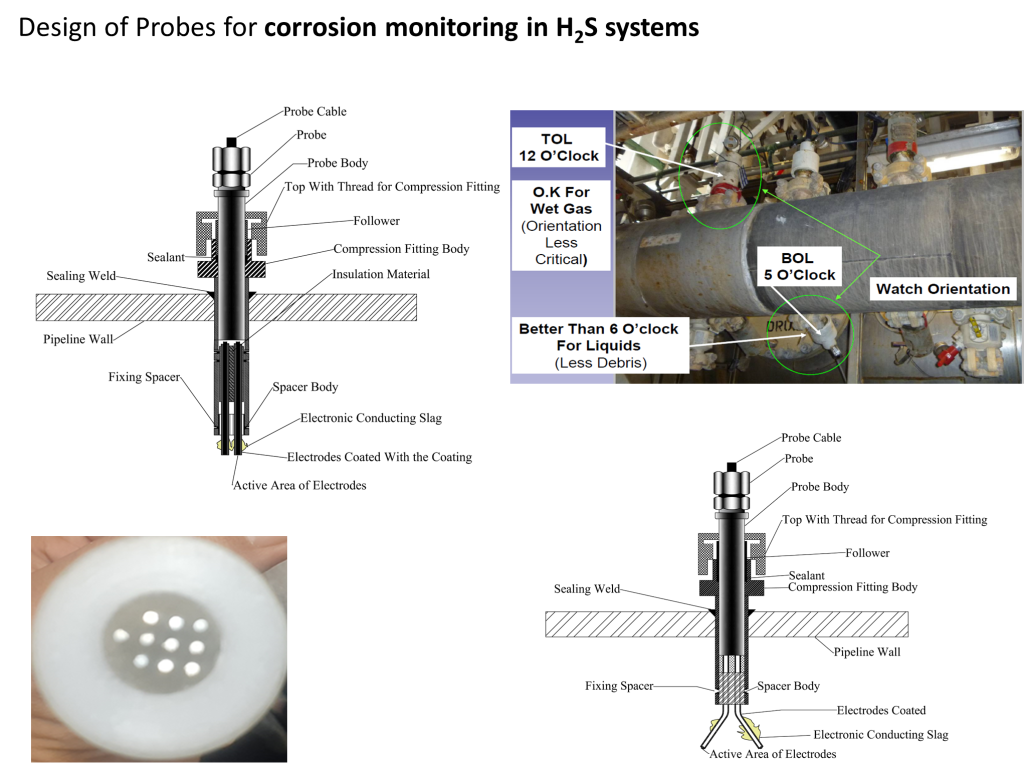

Due to the formation of sulphide compounds in the sour gas environment, the available commercial probes (ER probe) do not provide accurate and reliable data and must be replaced or washed frequently, so that it is practically impossible to evaluate the corrosion momentarily. To solve this challenge, our technological solution is to design and manufacture a new type of corrosion probe based on ZVA or ZRA technology. These types of probes are new generation corrosion monitoring tools with a special electrode configuration and the monitored quantity is the corrosion current. In this project, two or three models of this type of probes along with a corresponding data logger will be designed and built, and will be installed, tested and commissioned in the desired location of the Central Regions Oil Company. Probes and their data loggers will be produced according to ISO 2020 standard (zero-resistance circuit or zero-voltage circuit). The measuring circuit is designed in such a way that no additional potential / current is applied to the probe and the actual conditions of the pipeline will completely prevail at the level of the probe, which is an important advantage of these probes compared to existing commercial competitors. Due to the special geometric form and the technology used in the measuring circuit, the formation of conductive deposits of sulphide compounds in the sour gas environment does not affect the performance of the built probe and the measured corrosion data is reliable. Therefore, two important advantages of obtaining corrosion data with less error and longer operation time (increasing the monitoring range) will be obtained in comparison with ER probes. Finally, corrosion monitoring equipment including two probe models with multi-channel cable connected to data logger with offline / online monitoring of corrosion data will be installed, tested and quality evaluated at the location desired by the client. Also, according to the ASTM G102-23 standard, a completely updated software specially made for the probe will be provided for the calculation and analysis of corrosion data.